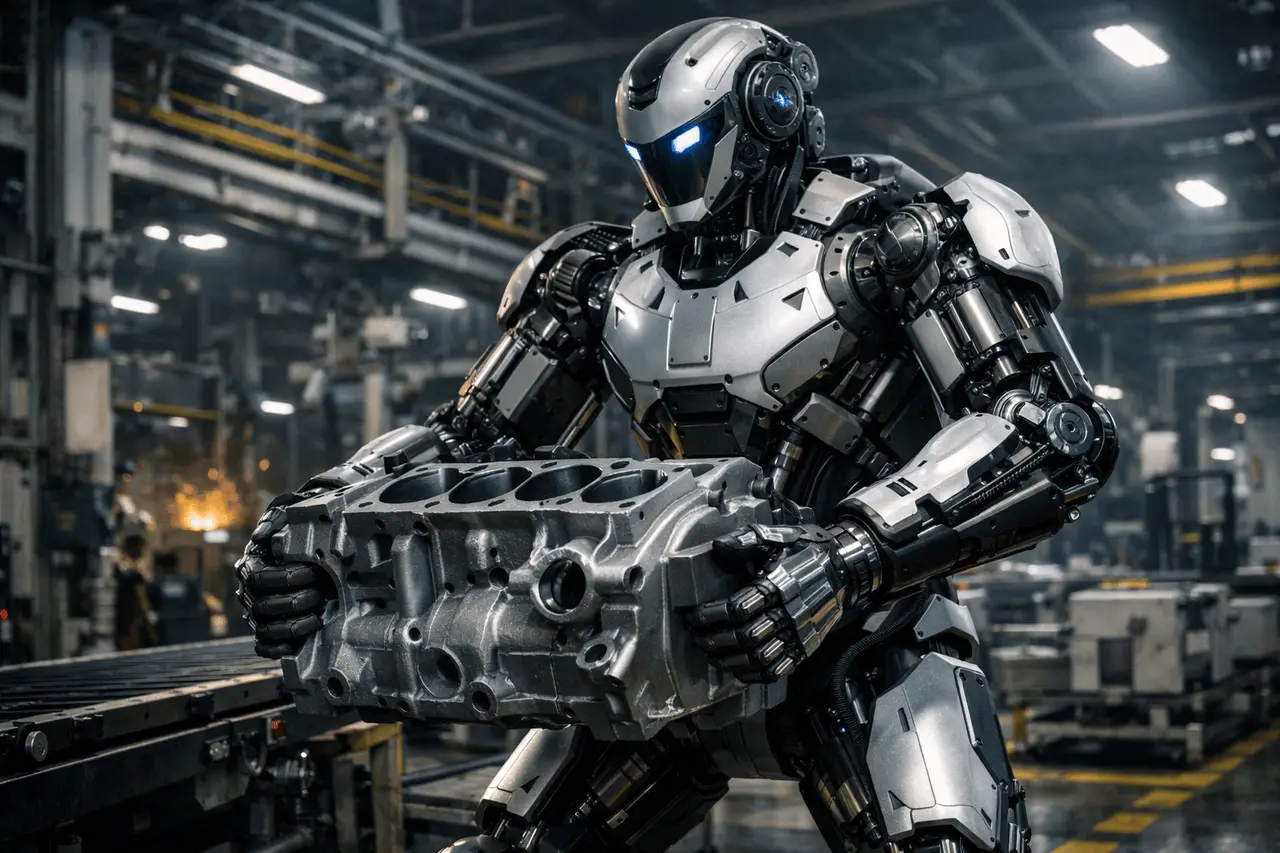

Galbot S1 humanoid robot is a revolutionary robot. Galbot is an impressive leap forward in industrial robotics, taking on a longstanding challenge in the safety and autonomy of heavy loads on production lines. While most humanoid robots are limited to light tasks, the S1 is designed for high-intensity industrial work, where coordination, strength, and autonomy are essential.

Created to work without remote control, the S1 targets workplaces where physical and repetitive labor is commonplace, and reliability is just as important as power. The introduction of the S1 is indicative of a broader transformation in industrial automation, moving away from robots that just move materials to machines capable of actively manipulating and operating in complex workspaces.

What Is the Galbot S1?

Galbot S1 is a heavy-duty humanoid robot designed to be used in industrial environments. In contrast to research- or service-oriented humanoid platforms, it is focused on physical tasks traditionally performed by humans.

One of the most distinctive features is its dual-arm payload capabilities of up to 50kg (approximately 110 pounds). If it can reach this level, it puts the S1 into a class that can bridge the gap between conventional industrial manipulators and general-purpose humanoid robots.

The system is developed by Galbot, with a focus on embodied intelligence, integrating perception, decision-making, and physical control into a unified autonomous platform.

Why Heavy-Duty Humanoid Robots Matter?

Industrial automation has long relied on fixed robot arms, automated guided vehicles (AGVs), and conveyor systems. Although they are effective, these systems aren’t as flexible as production lines shift or when the tasks require human ability.

Humanoid robots with heavy-duty capabilities solve a range of persistent issues:

- Intensity of Work: Repetitive lifting and handling can increase the risk of injuries for human workers.

- Labor Shortages: The logistics and manufacturing industries are facing ongoing labour shortages.

- Flexibility in Operation: Humanoids can adapt to layouts of the present without major overhauling.

Combining strength with movement and manipulation, robots, such as the S1, are designed to enhance, not replace, traditional automation.

How the Galbot S1 Works?

The core in S1 is an independent, embodied transport model that allows it to function without a remote. This model tightly integrates perception, motion planning, and actuation.

Essential technical elements are:

- Integrated Perception: Visual sensors and sensor systems allow the perception of space for loads, tools, and obstructions.

- Locomotion with Coordinates: The coordination of the hand-eye and foot is vital because mechanical stress is increased when you have heavier payloads.

- Balance Control Dynamic: Stability when lifting or moving large loads is crucial for ensuring safety.

A 50kg weight is not just about the strength of the motor. Every movement increases stress and torque across joints and requires precise, real-time adjustments to prevent component fatigue or instability.

Core Specifications at a Glance

| Feature | Galbot S1 |

|---|---|

| Robot type | Humanoid industrial robot |

| Payload capacity | Up to 50 kg (dual-arm) |

| Operation mode | Fully autonomous |

| Primary environment | Factory and production lines |

| Key capability | Heavy-load manipulation with coordination |

Real-World Industrial Applications

The S1 is designed for high-intensity, continuous tasks that require human-like reach and mobility. Examples of typical applications include:

- Materials Handling: Lifting or shifting significant components.

- Support for production Lines: Feeding machines or moving assembly pieces between stations.

- Operations in Warehouses: Manipulating heavy objects that are beyond the reach of light robots.

Since the robot has been built to operate within existing industrial space designs, it can minimize the need for custom fixtures or tools.

Use Cases by Industry

| Industry | Example Tasks | Operational Benefit |

|---|---|---|

| Manufacturing | Component transfer, line loading | Reduced physical strain |

| Automotive | Handling heavy sub-assemblies | Improved consistency |

| Logistics | Pallet-level manipulation | Increased throughput |

Comparison With Other Heavy-Payload Humanoids

The S1’s payload capacity is in line with industry benchmarks. Other robotics companies are seeking the same range of performance, such as Lumos and Damon Technology.

This implies that 50kg Dual-arm manipulation could be considered a realistic limit for industrial impact, significant enough to replace hard manual labor yet easily controlled within a humanoid dimension.

Benefits of the Galbot S1

The advantages of deploying an industrial-grade humanoid robot are:

- Self-Determination: Continuous operation without teleoperation decreases requirements for supervision.

- Strength and the Ability to Manipulate: Combines industrial-grade payloads and human-like control.

- Flexibility: Capable of working in environments specifically designed for people and not just machines.

These advantages make the S1 especially appealing to facilities looking to improve their automation without a complete line overhaul.

Limitations and Practical Considerations

Despite its capabilities, humanoid robots with heavy-duty capabilities face fundamental limitations:

- Price and Complexity: Advanced sensors, actuators, and control systems can increase deployment costs.

- Integrative Effort: Validation of safety and workflow integration is still crucial.

- Maintenance Demands: High mechanical stress requires rigorous upkeep schedules.

Companies considering adoption must weigh these factors against the security and productivity gains.

The Broader Shift in Industrial Robotics

The appearance of robots like the S1 illustrates a larger transition. Traditional AGVs concentrate on moving items from one point to another. Humanoid systems of today are designed to work and move within a space, completing tasks previously thought too difficult or beyond the capabilities of autonomous machines.

This new technology will bring industrial robotics closer to general-purpose, flexible automation – an essential step for factories that face fast-paced change.

My Final Thoughts

This Galbot S1 Humanoid Robot demonstrates how industrial automation is moving beyond isolated machines towards autonomous systems that can perform physical tasks, with a 50-kg dual-arm payload and automated, coordinated control to tackle jobs previously entirely dependent on human power.

As factories seek more secure, flexible operations, heavy-duty humanoid robots will play a greater role. The S1 serves as a good illustration of how strength, adaptability, and intelligence can combine to transform the role robots play in factories and the future of industrial automation.

FAQs

1. What exactly does the Galbot S1 humanoid robot do?

The Galbot S1 is designed for heavy industrial jobs, such as lifting or handling large parts on factory production lines.

2. What is the maximum weight that the Galbot S1 can lift?

The robot can support a double-arm load of up to 50kg (about 110 lbs), enabling it to handle an actual heavy-duty load.

3. Do you think Galbot S1 Galbot S1 require remote control?

No. The S1 is fully autonomous and operates with an integrated embodied control model, with no teleoperation.

4. What is this Galbot S1 different from traditional industrial robots?

In contrast to fixed or fixed-arm AGVs, the S1 combines the human-like movement of a robot with heavy-load capability in a single platform.

5. Is the Galbot S1 appropriate for existing factories?

Yes. The humanoid design enables it to operate in a space designed for humans, reducing the need for extensive infrastructure adjustments.

Also Read –

Helix 02: Whole-Body Autonomous Humanoid Model